Carbon fiber rims growing in popularity, why?

The advantages of carbon fiber presumably we all know. They are lighter, stiffer and stronger; however, most people only know carbon by these general advantages. Even many professional athletes at the top level do not understand the technology that goes into their carbon fiber rims and what makes them so great in comparison to rims made from different materials.

Carbon Fiber Cloth

The first thing to talk about is more obvious carbon fiber cloth, carbon fiber is a very thin fiber, but to use carbon fiber materials, the first of these fibers into cloth, which is carbon fiber cloth.

UD, unidirectional

Many riders believe unidirectional fiber isn't good, cheap, in fact, that's completely not the case. Carbon fiber is a bundle, the carbon fibers arranged in a row in one direction, that is, unidirectional fiber. This is simply the arrangement of carbon fibers, and carbon fiber material itself has nothing to do with the quality.

The advantage of unidirectional fiber: strength and stability, the angle may be designed to stack, inexpensive, to deal with the design angle different direction of the force. Unidirectional fiber is used most often in rims and frames, with higher strength along the direction of the carbon fibers. That is also why using unidirectional fiber instead of woven carbon fiber creates stronger frames & rims

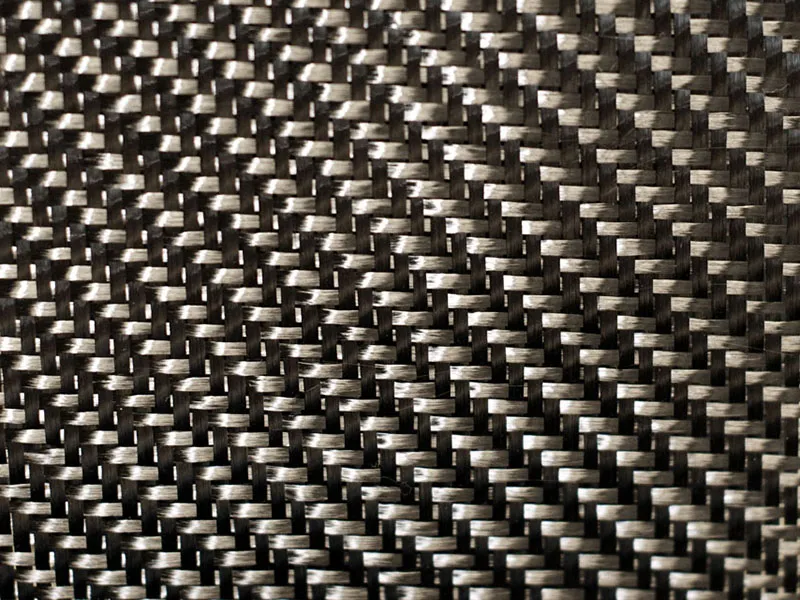

Woven carbon fiber

Woven carbon fiber is often said that 1K, 3K, 12K, 18K carbon fiber cloth, and carbon fiber itself also does not matter. The meaning of 1K is a carbon fiber composed of 1000, and then woven together; 3K is 3000, 12K is 12000. 18K is 18000, easier to understand. Carbon fiber is measured by the width of the fabric. For example, a knit width of 1K is about 1 millimeter, while a 12K fabric is larger at about 12 millimeters, and so on.

The advantages of woven carbon fiber: the smaller the carbon is woven out the more visually appealing it will be.

Modulus

In short, the modulus is hardness. Hear the high modulus can often think of lighter and harder, high modulus carbon fiber is harder, but the actual is not the harder the better, the rim design will also be integrated with other factors, such as comfort, strength.Stiffness

Stiffness is the above-said modules, with two different modules, imagine a slab 5cm wide, 50cm long and 2mm thick. When you suspend a 5kg weight from the end of the slab, the loading will be expected to result in bending and the degree of bending will correspond to rigidity. For different materials, a slab of the same thickness will show different bending properties. The stiffer the material, the less bending will happen. After the load has been removed. The slab will resume its original shape.Strength

The same is still the above slabs, but this time is fixed at both ends, and then force pull out. When it is torn off, it takes more force and greater strength.Resin

Just talk about it. Carbon fiber is barely any strength before it is coated with resin, and becomes harder than iron and stronger than steel when coated with resin.If you want to know what carbon fiber is, please click the link https://btlos.com/what-is-carbon-fiber-and-why-would-you-choose-carbon-fiber-rims.html