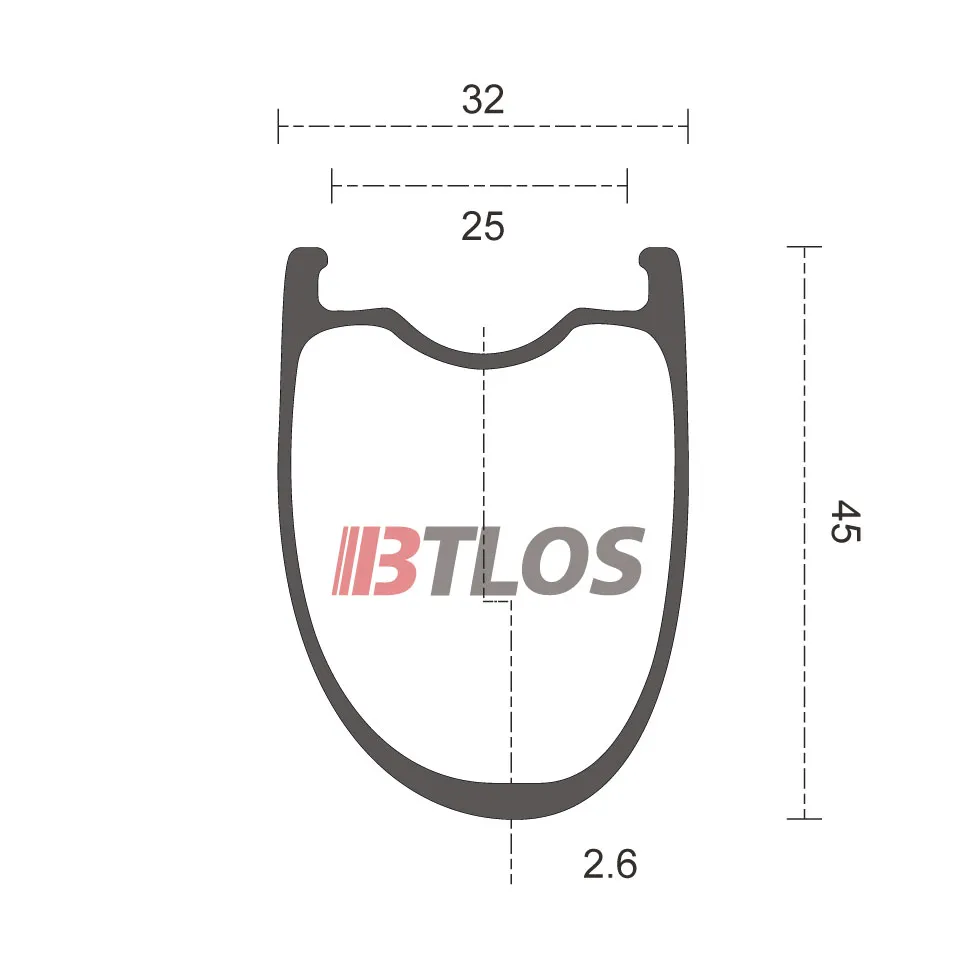

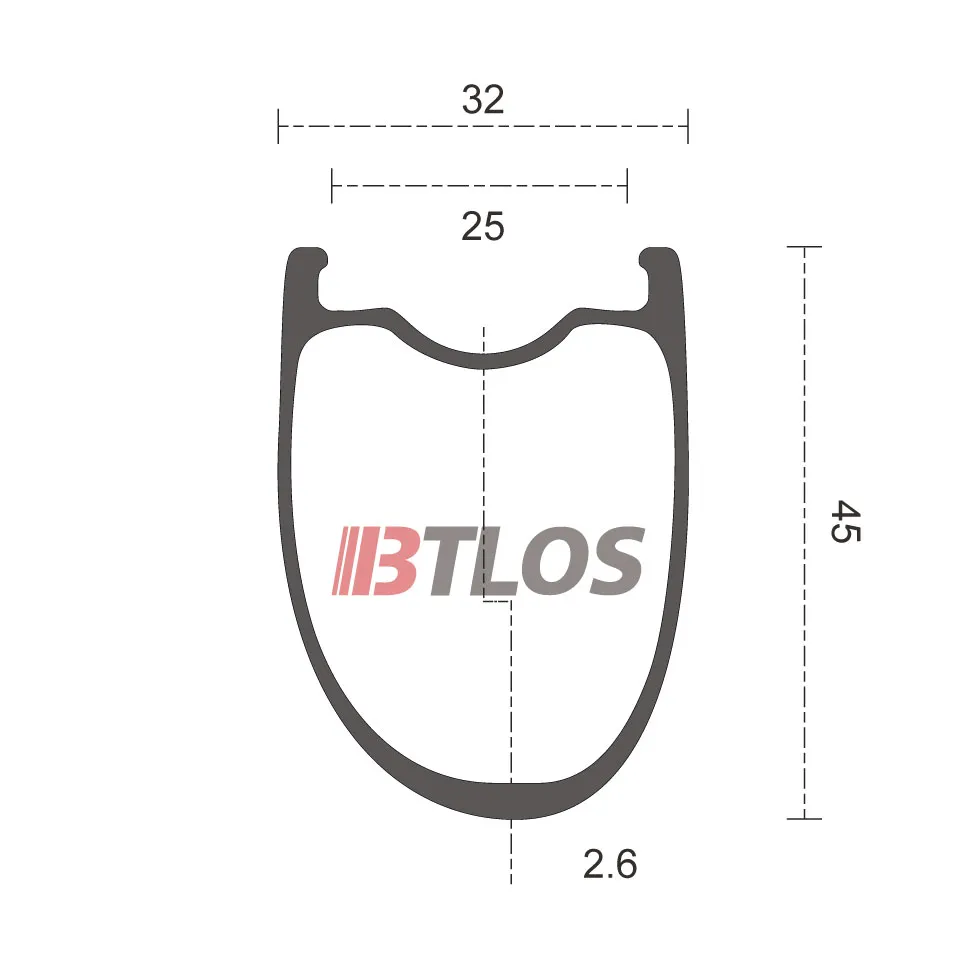

All Road 25mm Inner Width 45mm Depth Clincher Asymmetric Carbon Wheelset

- The 25mm internal width is compatible with a wide range of tire widths, making it suitable for road cycling, off-road riding, and various challenging terrains.

- The 45mm rim height is engineered to reduce wind resistance, enhancing speed and efficiency during rides.

- The wide rim design and asymmetric structure excel in off-road and challenging terrains, offering durability and stability.

This asymmetric carbon fiber wheelset, with a 45mm height, 32mm external width, and 25mm internal width, combines high-performance carbon fiber material with optimized aerodynamic features. It offers exceptional performance and a comfortable riding experience for cycling enthusiasts.

Weight:

1324.8+/-25g (With Extralight Rims, Carbon Spoke Hub & Carbon Spoke)

Material:

Extralight: 50% T700 + 50%T800 carbon Fiber

Premium: 80% T700 + 20%T800 carbon Fiber

Standard: Full T700 Carbon Fiber

ERD:

549mm

( Does not include the nipple )

Max Spoke Tension:

130kgf

Max Rider Weight:

Premium/Standard: 120kgs;

Extralight: 95kgs

Max Tire Pressure:

100psi

Hole Count:

28H/28H, 32H/32H

Technologies

Smooth Inside Wall

The traditional inflatable bladders used by many manufacturers to maintain the rim's shape during the molding process lack the ability to closely control the final shape of the rim. As a result, although most carbon rims appear smooth and seamless on the outside, they are marked by irregularities and weaknesses on the inner surface of the rim. Each irregularity is a potential point of failure.

Using a molding process we call ''SLW'', BTLOS employs proprietary high-pressure bladders and specific solid silicone forms to tightly control rim shape, producing virtually void-free rims with perfectly smooth walls (inside and out) resulting in finished rims that are truer, lighter, stronger, more durable rims and wheels.

USED FOR: Premium Series

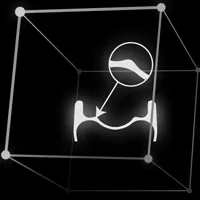

Spoke Hole Angles

BTLOS can drill spoke hole angles to match or compliment the spoke angles created by the hub flange (as provided by the customer). Matching the spoke hole drilling angle in the rim to the spoke angle of the hub/hub flange allows the nipple to be better aligned with the spoke when the wheel is tensioned resulting in fewer broken spokes and nipples.

USED FOR: Premium Series / Standard Series

One-Piece Molding

Since the rims do not have the weaknesses associated with the various components of any of the different designs, they are continuously molded using techniques known as "one-piece molding". Because of this, the rims are perfectly symmetrical and evenly rolled.

USED FOR: Premium Series / Standard Series

Twine Tec

Twine technology can solve the problem of using a material with insufficient ductility to produce a full three-dimensional surface product that is prone to local tearing or wrinkling of the material. This will ensure even balance of weight and strength around the circumference of the rim.

USED FOR: Premium Series / Standard Series

ISO-Etrto Compliant

Internationally standardized tire bead and rim sizing. This ensures that the fit and relationship between a rim and a tire are as secure as possible.

USED FOR: Premium Series / Standard Series

Outstanding Materials

The finest carbon sheets are selected based on years of knowledge and experience. Superior workmanship is executed and ensured by well-trained factory staff.

USED FOR: Premium Series / Standard Series

3D Drilling

A computer controlled drilling machine ensures accurate drilling that can be replicated time after time.

USED FOR: Premium Series / Standard Series

U shape

Modern more rounded U shape profile has enabled aerodynamics, which means improved traction while reducing the rolling resistance.

USED FOR: Premium Series / Standard Series

Tubeless Compatible

It is suitable for tubeless tires. This makes it possible to achieve a smaller overall system weight while improving puncture resistance. The precision diameter achieves a reliable tubeless performance.

<br>USED FOR: Premium Series / Standard Series

Bead Lock

The small ridges on either side of the drop channel help secure tubeless tires in place. The bead lock makes it easier to seal up tubeless tires with a floor pump, and they are incredibly hard to burp.

USED FOR: Premium Series / Standard Series

Hand-Built

All BTLOS wheels are 100% hand built to exacting standards by well trained wheel builders using only the best available components. All of our wheels are rigorously tested to guarantee accurate spoke tension and precise truing.

USED FOR: Premium Series / Standard Series

Two Carbon Fiber Types

Rims made from different types of carbon fibers may thus be characterised by greater stiffness and strength. Therefore, in order to provide you with the best possible rims, we use two different types of carbon fiber (Toray T700, Toray T800) in the production of BTLOS rims. BTLOS premium rims are a combination of T700 and T800 carbon fibers.

USED FOR: Premium Series / Standard Series

Extra Carbon Fiber Strip

Around the spoke holes, each rim is reinforced with an extra carbon fiber rod. Its precise arrangement allows for the greater tension of the spokes, which results in a high rigidity of the rims.

USED FOR: Premium Series / Standard Series

Quality Control Systems

We believe the reliability, and consistent quality of our products has the best value in the industry.

In order to ensure that BTLOS rims not only meet international safety requirements but also comply with additional, higher quality standards, we use SGS and EN 14781 standards when manufacturing rims.

USED FOR: Premium Series / Standard Series

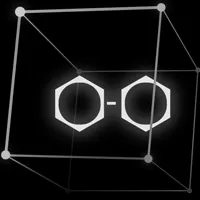

Double Triangle Design

The BTLOS bead seat/sidewall interface is created for the tire bead based on the structural advantages of a triangle. This solution increases the strength and ability of the of the rim to withstand impact. Further, the triangular shape of this design also ensures the stability of the rim sidewall under hard braking while delivering excellent strength-to-weight performance.

USED FOR: Premium Series / Standard Series

Ultralight Construction

BTLOS applies firsthand knowledge and research, along with industry-leading materials and technologies to create rims and wheels that are optimized to deliver extremely light weights without sacrificing the strength and durability demanded by the world's best riders.

USED FOR: Premium Series

Flatness And Roundness

BTLOS employes molding and manufacturing techniques which allow us to control rim flatness to within 0.15mm and roundness to withing 0.2mm making it incredibly easy to build perfectly true, strong wheels.

USED FOR: Premium Series

Stiffness

BTLOS considers the intended application of each rim design, tailoring the relative stiffness of our rims to achieve maximum power transfer.

USED FOR: Premium Series / Standard Series

45 Degree Overlap

A lay-up process where by carbon layers are stacked/overlapped at 45-degree angles creating very high lateral stiffness and improved impact resistance while maintaining responsiveness and efficiency under power.

USED FOR: Premium Series / Standard Series

CNC Cutting Material

Computer Controlled machinery is used to plan, format and cut carbon sheets in order to achieve the most efficient use of materials and to control costs while also making measurements and cuts controlled within 0.1mm allowing us to deliver outstanding lay-up consistency on each and every rim we build.

USED FOR: Premium Series / Standard Series

Aerodynamic Profile

Improved aerodynamic design for a better crosswind protection.

USED FOR: Premium Series / Standard Series

Related Products

Rims Depth

Recommended Tubeless Valves Length

under 26mm

35mm

..

7.00 USD

The high tensile tubeless tape features a natural rubber adhesive that does not leave a residue on the rims...

6.00 USD

VTIS

MTB Valve stem and tape installation service

MTB Provide a pair of valve stems and a roll of tape, and install them on the wheel set you bought...

15.00 USD

ARC45A

ARC45A Asymmetric 25mm Inner Width 45mm Depth All Road Disc Carbon Rims

BTLOS All Road series 25mm inner width 45mm depth rims specifically made for disc brakes.

Featuring a disc specific carbon construction, and..

185.00 USD