-

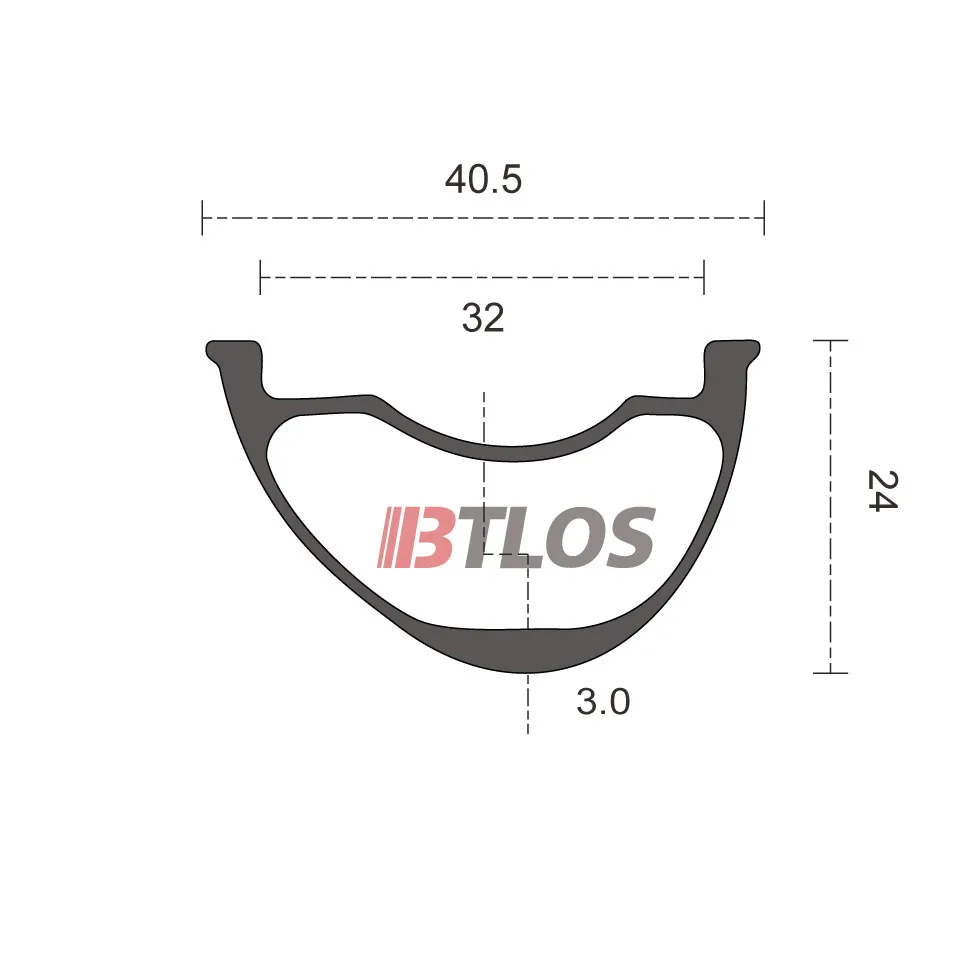

WM-i32AE

Extralight 32mm Internal Width Enduro/Downhill Carbon Wheelset

- Starting at:

- 896.00 USD

Introducing the M-i30AE, the ultimate choice for aggressive riders. Crafted with superior materials and technology, this rim offers exceptional strength and durability while minimizing weight, enhancing your riding performance.

Superior Material Combination: Constructed using 80% T700 carbon fiber and 20% T1100 carbon fiber with special high-toughness resin. This ensures high strength, stiffness, and improved toughness. It better disperses stress upon impact while maintaining a lightweight design, suitable for various rigorous riding conditions.

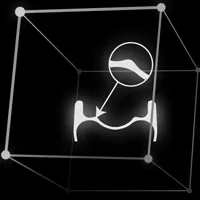

Special tire lip design: The bead design on the outer wall of the tire lip provides better shock dispersion and prevents the tire from snakebiting on impact, offering an additional layer of security.

High Quality: The rims have passed the rigorous 175J (DH) and 155J (EN) tip impact tests, ensuring exceptional durability and performance in the toughest conditions.

This rim is the ideal choice for Enduro and Downhill enthusiasts. Whether on rugged mountain trails or high-speed downhill runs, it offers unmatched performance and reliability. Choose this ultra-light carbon fiber rim and experience the endless possibilities of riding.

( Does not include the nipple )

Technologies

Smooth Inside Wall

Using a molding process we call ''SLW'', BTLOS employs proprietary high-pressure bladders and specific solid silicone forms to tightly control rim shape, producing virtually void-free rims with perfectly smooth walls (inside and out) resulting in finished rims that are truer, lighter, stronger, more durable rims and wheels.

USED FOR: Premium Series

Spoke Hole Angles

USED FOR: Premium Series / Standard Series

One-Piece Molding

USED FOR: Premium Series / Standard Series

Twine Tec

USED FOR: Premium Series / Standard Series

ISO-Etrto Compliant

USED FOR: Premium Series / Standard Series

Outstanding Materials

USED FOR: Premium Series / Standard Series

3D Drilling

USED FOR: Premium Series / Standard Series

Tubeless Compatible

Hookless

Asymmetric

USED FOR: Premium Series / Standard Series

Bead Lock

USED FOR: Premium Series / Standard Series

Two Carbon Fiber Types

USED FOR: Premium Series / Standard Series

Extra Carbon Fiber Strip

USED FOR: Premium Series / Standard Series

Quality Control Systems

USED FOR: Premium Series / Standard Series

Double Triangle Design

USED FOR: Premium Series / Standard Series

Ultralight Construction

USED FOR: Premium Series

Flatness And Roundness

USED FOR: Premium Series

Stiffness

USED FOR: Premium Series / Standard Series

45 Degree Overlap

USED FOR: Premium Series / Standard Series

CNC Cutting Material

USED FOR: Premium Series / Standard Series

Related Products

MTB Valve stem and tape installation service

MTB Provide a pair of valve stems and a roll of tape, and install them on the wheel set you bought...