How BTLOS Rims Passed the UCI Test and Why It Matters

If you are a cycling enthusiast, you may have heard of the UCI test, a rigorous certification process that evaluates the quality and performance of bicycle components. The UCI test is conducted by the Union Cycliste Internationale (UCI), the world governing body for cycling sports. Only products that meet the UCI's high standards can be used in official UCI events, such as the Tour de France, the Olympic Games, and the World Championships.

The UCI test covers various aspects of bicycle components, such as weight, strength, stiffness, aerodynamics, durability, and safety. The test is designed to ensure that the components are reliable, efficient, and fair for all competitors. The test also aims to promote innovation and development in the cycling industry.

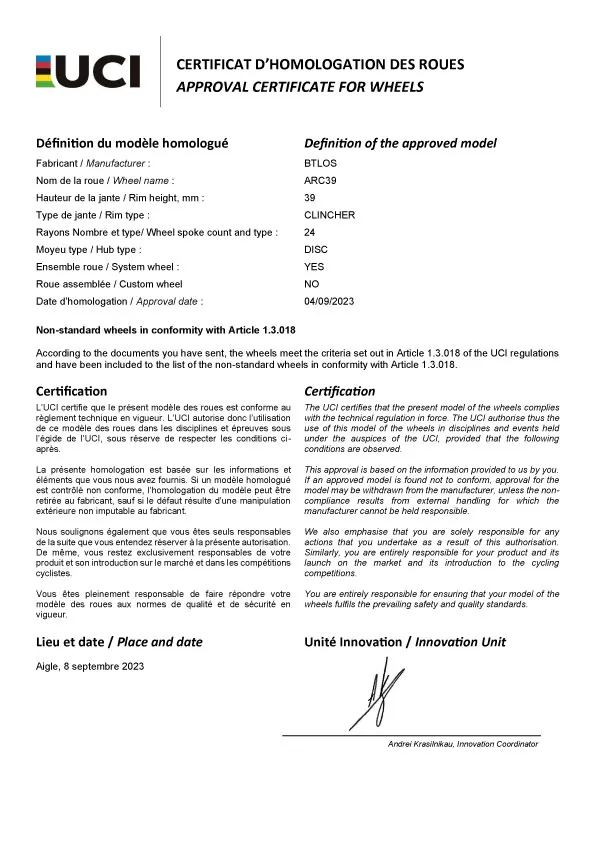

Recently, our ARC39 carbon fiber wheels passed the UCI test and performed extremely well, meeting all UCI requirements, proving their high quality and performance. We will make more of our models obtain UCI certification in the future.

What does BTLOS wheel UCI approval mean?

- For riders, if you are competing in a race that requires UCI approved rims then you can choose our UCI approved wheels

- For OEM customers, we can test your wheels for you and provide you with all the information you need for UCI certification to help you build your brand image. We have helped many brands complete their UCI certification.

UCI Wheel Test Conditions

- Test method: Vertical drop test (neutralization of the rebound of the anvil)

- Wheel: Wheel tested without tire

- Impact striker geometry: Flat steel anvil, the impact surface is covered with a silicone rubber pad of 20mm thickness

- Hitting point: One hit at 90° from valve hole, the point between the spokes

- Impact mass: 10kg

- Impact energy: 40 Joules

Failure criteria (for alloy and carbon wheels)

- No visible cracks or delamination

- No change in lateral profile or in lateral run out in excess of 1.0mm

- No change in radial profile or in radial run out in excess of 1.0mm

BTLOS excellent test results

We used the standard series of ARC39 wheel for testing. After the test, the lateral runout and radial runout of the wheel only changed by 0.07mm and 0.05mm. This is a very amazing result.

Lateral/Radial runout:

| Lateral runout | Radial runout | |

|---|---|---|

| Before the test: | 0.13mm (0.05/-0.08mm) | 0.20mm (0.11/-0.09mm) |

| After the test: | 0.20mm (0.07/-0.13mm) | 0.25mm (0.15/-0.10mm) |

| Difference: | 0.07mm | 0.05mm |

There are currently many brands of carbon fiber wheels approved by the UCI, but few manufacturers can produce similar wheels that can only produce such a small jump after UCI testing.

The BTLOS ARC39 UCI test video

UCI certificate for the BTLOS ARC39