Learn more and get the discount code.

-

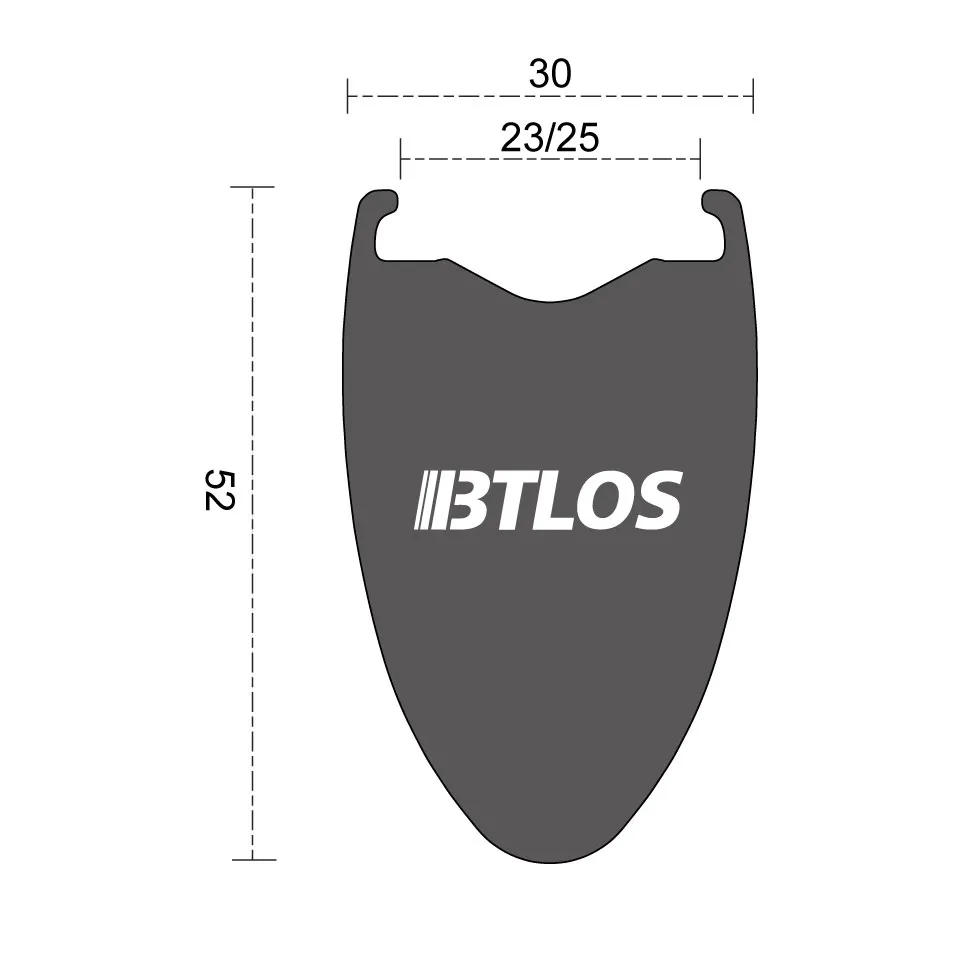

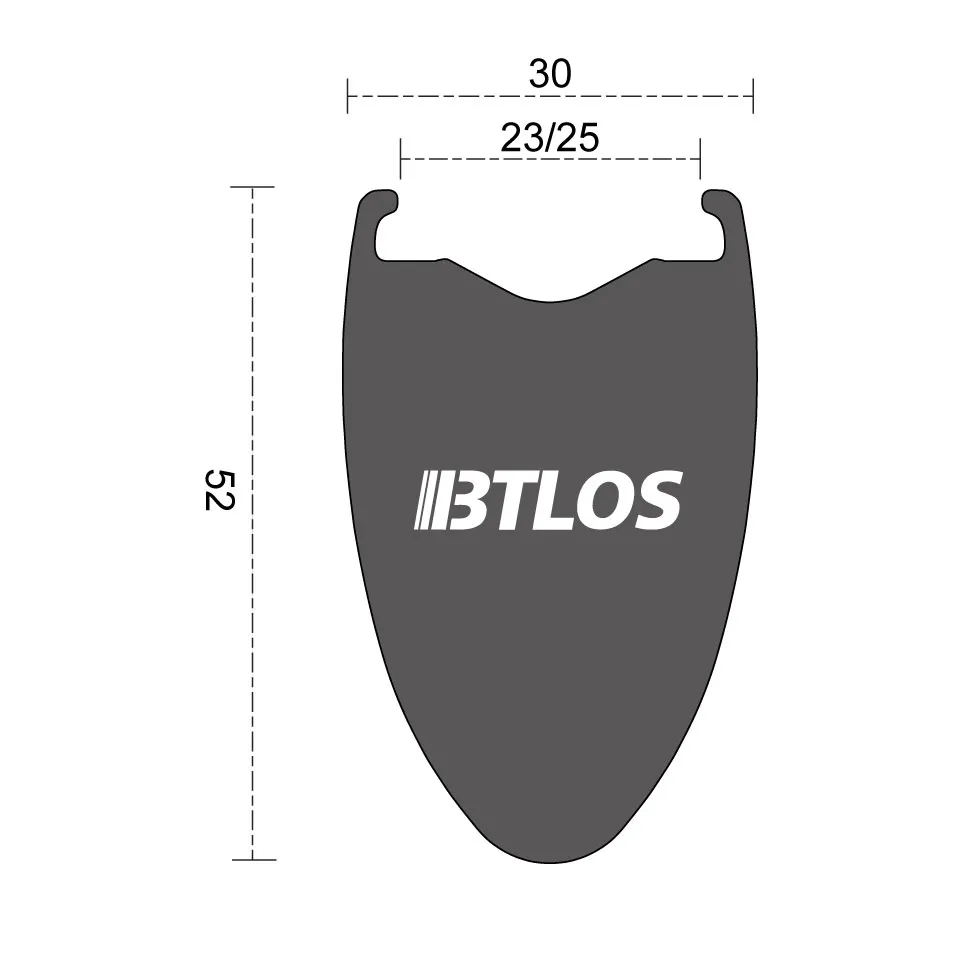

AERIX PRO RS52

AERIX PRO RS52 – Light. Fast. Unstoppable

- Starting at:

- 299.00 USD

The AERIX PRO RS52 is a 52mm road rim engineered to deliver the perfect balance of climbing efficiency and aerodynamic speed.

With its exclusive Fiber-Continuous Spoke Hole Design and bowl-shaped spoke seat platform, every spoke sits perfectly, making wheel building easier and ensuring long-lasting, rock-solid durability.

A smart front–rear layup keeps the front rim feather-light and agile at 335g, while the rear rim maximizes power transfer at 370g, giving you explosive acceleration and stable handling.

Each rim exceeds expectations by passing UCI impact testing at 90J (no tire mounted) — double the official requirement — with zero fractures or delamination.

Thanks to precise roundness, optimized carbon layup, and advanced mold design, the RS52 is not just lighter — it’s stronger than many ultra-light competitors, giving you the confidence to push harder, climb faster, and ride longer.

Front–Rear Differentiation for Balanced Performance

The AERIX PRO RS52 employs a differentiated layup strategy to achieve the ideal balance between weight, compliance, and power transfer:

- Front (335g): Lightweight and compliant, optimized for precise steering and agile handling.

- Rear (370g): Reinforced for efficient torque transfer and higher load capacity.

Load Rating:

- Front rim(335g) + rear(335g) recommended for riders under 100kg

- Front 335g + Rear 370g combination: supports up to 115kg total rider system weight

The default is 25mm inner width, If you prefer the 23mm inner width or a different front–rear weight combination, please specify it in the order notes.

For a detailed look at the design philosophy, testing standards, and real-world advantages behind the RS52.

( Does not include the nipple )

Front Extralight + Rear Premium: 115kgs

Technologies

Fiber-Continuous Spoke Hole Design

Traditional carbon rims often require post-production drilling for spoke holes, which can compromise fiber continuity and create stress concentration areas.

Fiber-Continuous Spoke Hole Design, reinforced during the layup stage for continuous fiber alignment and even stress distribution.

Smooth Inside Wall

Using a molding process we call ''SLW'', BTLOS employs proprietary high-pressure bladders and specific solid silicone forms to tightly control rim shape, producing virtually void-free rims with perfectly smooth walls (inside and out) resulting in finished rims that are truer, lighter, stronger, more durable rims and wheels.

USED FOR: Premium Series

Spoke Hole Angles

USED FOR: Premium Series / Standard Series

Graphene Special Braking Surface

USED FOR: Premium Series

Super High TG Braking Surface

USED FOR: Premium Series / Standard Series

One-Piece Molding

USED FOR: Premium Series / Standard Series

High TG Epoxy Resins

USED FOR: Premium Series / Standard Series

Twine Tec

USED FOR: Premium Series / Standard Series

ISO-Etrto Compliant

USED FOR: Premium Series / Standard Series

Outstanding Materials

USED FOR: Premium Series / Standard Series

3D Drilling

USED FOR: Premium Series / Standard Series

U shape

USED FOR: Premium Series / Standard Series

Tubeless Compatible

Two Carbon Fiber Types

USED FOR: Premium Series / Standard Series

Extra Carbon Fiber Strip

USED FOR: Premium Series / Standard Series

Quality Control Systems

USED FOR: Premium Series / Standard Series

Double Triangle Design

USED FOR: Premium Series / Standard Series

Ultralight Construction

USED FOR: Premium Series

Flatness And Roundness

USED FOR: Premium Series

Stiffness

USED FOR: Premium Series / Standard Series

45 Degree Overlap

USED FOR: Premium Series / Standard Series

CNC Cutting Material

USED FOR: Premium Series / Standard Series

Aerodynamic Profile

USED FOR: Premium Series / Standard Series

Related Products

Bicycle tubeless rim valve stem

Rims Depth Recommended Tubeless Valves Length under 26mm 35mm ..

Tubeless rim tape

The high tensile tubeless tape features a natural rubber adhesive that does not leave a residue on the rims...

AERIX PRO RS52 Wheelset – Light. Fast. Unstoppable

The AERIX PRO RS52 is a 52mm road rim engineered to deliver the perfect balance of climbing efficiency and aerodynamic speed. With its exclus..